Creating bespoke designs focused upon practicality in a range of materials.

We have over 100 years worth of combined experience

Here at ASH Plastics we specialise in both the design and manufacturing of bespoke, precision items created using a range of materials and within a state of the art manufacturing facility. Because our team of experts have 100 years’ worth of combined, hands-on experience of delivering solutions, we create designs which are predicated on maximising the actual manufacturing process.

Flexible design process

When a client comes to us they are appointed a dedicated project manager who will work on their project every step of the way. In terms of design, this means liaising on the initial brief and then turning that brief into a visual representation.

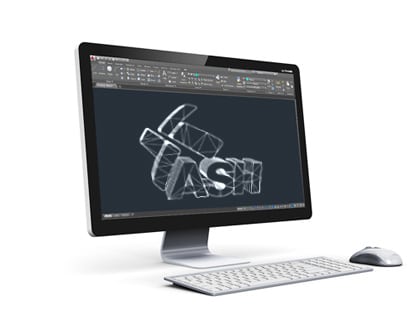

Our state of the art CAD technology is such that we can provide conceptual SolidWorks visuals all the way up to fully detailed engineering drawings, and the fact that we liaise so closely means that the designs can be tweaked and modified throughout to ensure that they remain fully consistent with your original intentions.

Because we also provide a one stop shop manufacturing service for our clients the designs we create are always focused on practicality and on the deliverability of the finished product.

A range of materials

We work with materials ranging from all types of plastic to wood, steel and glass and can create a design which optimises the use of material to deliver results which combine excellence with value for money.

Our team of experts are equally at home designing bespoke, branded retail display units as they are precision engineered components for specialist sectors such as defence or the automotive industry.

Having created your design we can use our 20,000 sq. ft. manufacturing facility to produce a prototype, establishing proof of concept and providing a three dimensional version of the finished product which can be used to decide any changes which need to be made to enhance effectiveness and/or streamline production.

Using the latest and most innovative materials

If needed, we can undertake the manufacturing of the design, using equipment which includes a Zund digital cutter, Biesse and Penta Laser CNCs and laser etching equipment.

Our knowledge of the manufacturing process, particularly with regards to plastic forming and fabrication, coupled with our links to suppliers across the globe, means that we are always able to incorporate the latest and most innovative materials into our designs, enabling clients to pursue targets such as lower costs or a reduced carbon footprint.

Contact Our Experts

If you’d like to learn more about the end-to-end one stop service we could provide for your company please get in touch. Our experts are ready and waiting to answer any questions and explain exactly what we could do to turn your ideas into a reality.

Call us or send an email and we’ll start the process of delivering the solutions you’re looking for.

Tel: +44(0)1902 450 300

Email: hello@ashplastics.co.uk