Vacuum Forming

Home » Plastic Forming & Fabrication Services » Thermoforming » Vacuum Forming

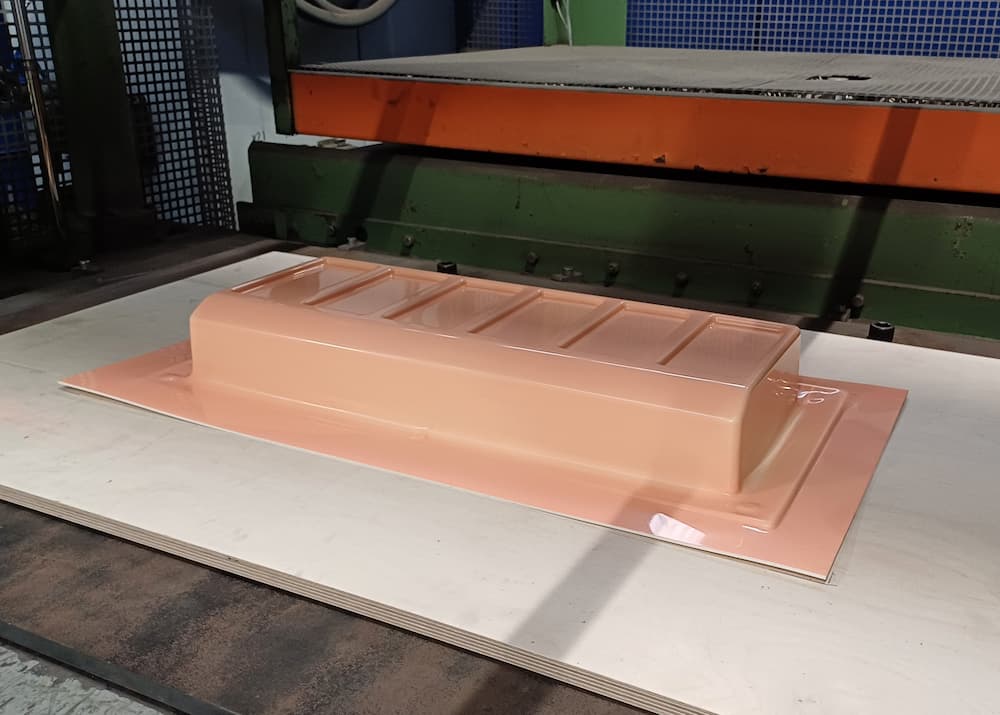

At A.S.H. Plastics we are specialists in delivering quality results manufacturing point of sale and display products from materials that include acrylic, polycarbonate, polypropylene, polyethylene, ABS and HIPS. One of the most common methods we use is thermo-forming. This is when heat is used to manipulate the raw plastic material, so it is sufficiently pliable, in order to bend or shape it a particular way. Line bending is used to put angles into cut plastics, drape forming allows a heated sheet or piece of plastic material to be shaped over a mould using gravity or a vacuum and dome blowing is the process of using air to force a uniformed spherical shape from a heated plastic sheet. Once these processes are complete the material is then left to cool and harden.

All of our thermo-forming manufacturing supports our other manufacturing techniques that include CNC and laser cutting, flame, mop and diamond polishing and various bonding techniques together with assembly and final boxing, to offer a complete manufacturing and delivery service.

Get in touch

We work with some of the biggest retail brands in the UK and many smaller independent retailers and businesses and we are ready to take on the next big industry challenge, that might just be your challenge too! Why not get in touch with us today.